- Siemens teamcenter for manufacturing manual#

- Siemens teamcenter for manufacturing full#

- Siemens teamcenter for manufacturing software#

“With single-purpose automation,” Helmke explains, “we call an external partner, who performs the programming, but they have to be called again anytime there is a product or process change.” An important key to meeting these goals is the team’s efforts to foster flexible automation. Succinctly put, the challenge for Helmke’s team is to meet the goals of quality, productivity, cost and time, achieving required production output levels.

Siemens teamcenter for manufacturing software#

“I’m convinced that we need software to handle that complexity.” Helmke’s team is responsible for all digital factory tools used at BSH Home Appliances, including those used for factory layout planning, production process planning, and process and logistics simulation. “As you can imagine, that brings quite some complexity into our factories, says Frank Helmke, head of the digital factory for BSH Home Appliances Group.

Siemens teamcenter for manufacturing manual#

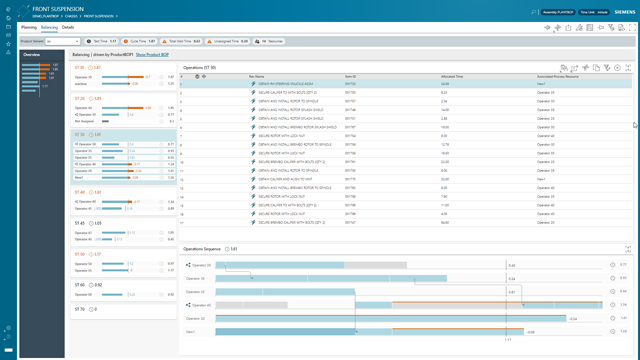

And assembly lines at the plants sometimes include upwards of 50 workstations, with a mix of manual and robotic operations. Additionally, each process must be tailored to the equipment and resources available at each factory.

Siemens teamcenter for manufacturing full#

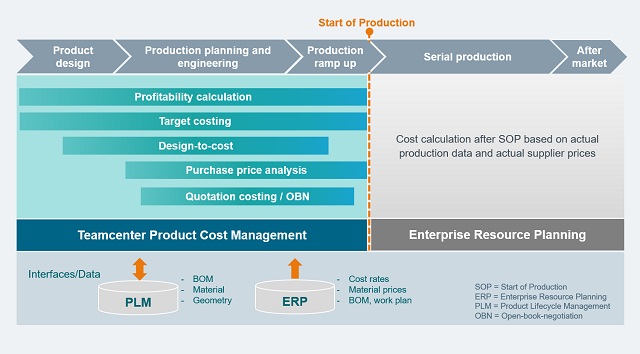

Not only does the company manufacture a large variety of products, it also handles a full range of manufacturing steps, from receiving sheet metal to form, weld, rivet, paint and/or enamel-coat appliance housings, all the way through to packaging and shipping the finished products. The manufacturing engineering team plans for these products while taking into consideration an unprecedented number of variables and factors. A refrigerator manufacturing line, for example, may run the same product platform for several years. The company’s team of manufacturing engineers must orchestrate the plans for its many factories and production lines, some of which support relatively long lifecycles for each product platform. With the proliferation of product variation, including both conventional home appliance technologies and new digitally personalized features, BSH designs and manufactures millions of different products each year.

BSH is digitalizing its own products – manufacturing appliances that also offer personalized digital features, services, and content – while digitalization is also transforming the company’s manufacturing floors.Īt Realize LIVE 2020, Siemens’ global customer event, BSH presented its approach to integrated digital product and process engineering for both manual and robotic operations on its assembly lines. The company manufacturers its entire range of home appliances at 38 factories worldwide. Munich-headquartered B/S/H/ (BSH) has grown since its 1967 founding from a German exporter to one of the world’s leading home appliance manufacturers. B/S/H/ leverages Tecnomatix, Teamcenter, and NX to optimize mixed robotic and manual assembly

0 kommentar(er)

0 kommentar(er)